IimotoI-shaft ayinamgongxo, inomsebenzi olungileyo wokulahla ubushushu kwaye inokukhuthaza ubunzima bokukhanyaimoto.Ngaphambili, i-motor shafts yayiyininzi eqinile, kodwa ngenxa yokusetyenziswa kwee-motor shafts, uxinzelelo lwaluhlala lugxininiswe kumphezulu we-shaft, kwaye uxinzelelo kwi-core lwaluncinci. Ngokweempawu zokugoba kunye ne-torsional ye-metical mechanics, inxalenye yangaphakathi yeimotoishafti yayigqobhozekile ngokufanelekileyo, kwaye kwakufuneka kuphela i-diameter encinci yangaphandle ukuze kwandiswe inxalenye yangaphandle. I-shaft evulekileyo inokuhlangabezana nokusebenza okufanayo kunye nokusebenza njenge-shaft eqinile, kodwa ubunzima bayo bunokuncitshiswa kakhulu. Okwangoku, ngenxa yokugotywa kweimotoshaft, i-oyile yokupholisa inokungena ngaphakathi kwi-motor shaft, inyuse indawo yokulahla ubushushu kunye nokuphucula ukusebenza kakuhle kokutshabalalisa ubushushu. Ngaphantsi kwendlela yangoku ye-800V ye-high-voltage yokutshaja ngokukhawuleza, inzuzo ye-hollow shafts yemoto inkulu. Iindlela zangoku zemveliso yeeshafu zemoto ezingenanto ikakhulu zibandakanya i-shaft eqinileyo, i-welding, kunye nokwakheka okudityanisiweyo, apho i-welding kunye nokwakheka okudibeneyo kusetyenziswa ngokubanzi kwimveliso.

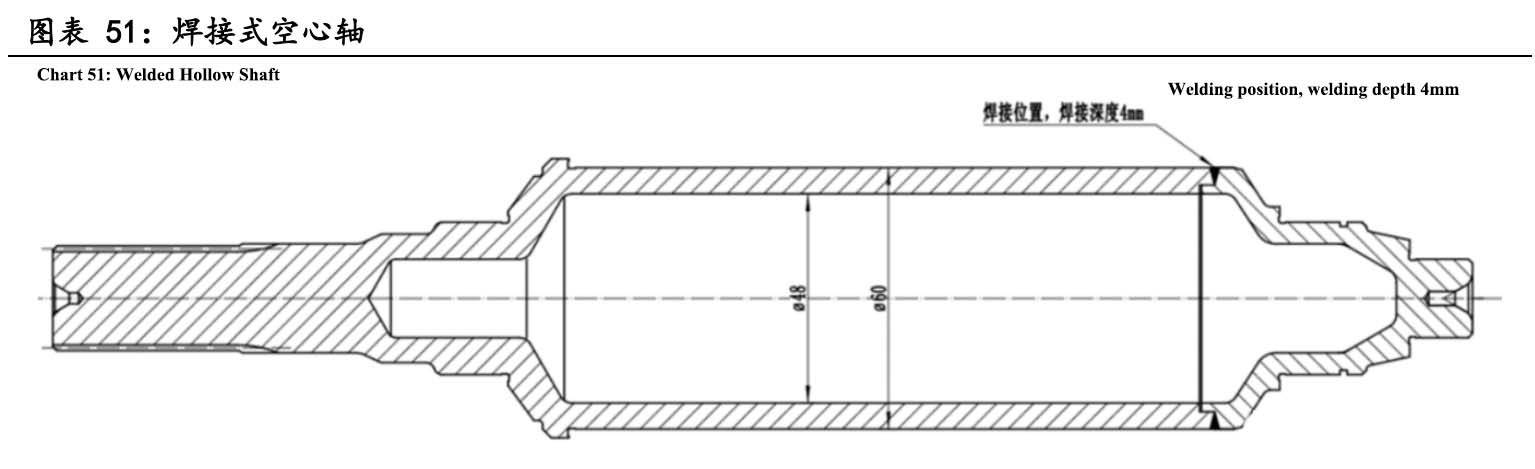

Ishafti ediyelweyo iphunyezwa ikakhulu ngokuyilwa kwe-extrusion ukuze kuphunyezwe umngxuma ongaphakathi onyatheleyo weshafti, emva koko yenziwe ngoomatshini kwaye idityaniswe ukumila. Ngokubunjwa kwe-extrusion, utshintsho lwemilo yomngxuma wangaphakathi kunye nesakhiwo semveliso kunye neemfuno zamandla zigcinwa kangangoko kunokwenzeka. Ngokuqhelekileyo, ubukhulu bodonga olusisiseko lwemveliso bunokuqulunqwa ngaphantsi kwe-5mm. Izixhobo ze-welding ngokubanzi zamkela i-butt friction welding okanye i-laser welding. Ukuba i-butt friction welding isetyenzisiwe, indawo yokudibanisa i-butt ngokubanzi malunga ne-3mm ye-welding protrusion. Ukusebenzisa i-laser welding, ubunzulu be-welding ngokubanzi buphakathi kwe-3.5 kunye ne-4.5mm, kwaye amandla e-welding anokuqinisekiswa ukuba mkhulu kune-80% ye-substrate. Abanye ababoneleli banokufikelela ngaphezu kwe-90% yamandla e-substrate ngokusebenzisa amanyathelo angqongqo olawulo lwenkqubo. Emva kokuba i-welding ye-shaft egobileyo igqityiwe, kuyimfuneko ukuqhuba uvavanyo lwe-ultrasonic okanye i-X-ray kwi-microstructure kunye nomgangatho we-weld wendawo ye-welding ukuqinisekisa ukuhambelana kwemveliso.

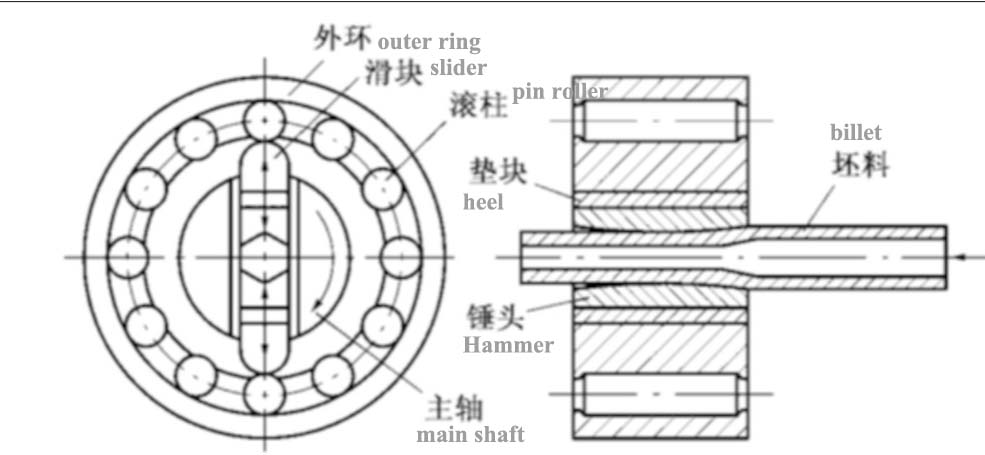

Ishafti edibeneyo eyenza umngxuma wenziwa ikakhulu zizixhobo zangaphandle kwindawo engenanto, eyenza ukuba indawo yangaphakathi iphumeze ngokuthe ngqo umngxuma ongaphakathi weshafti. Okwangoku, i-radial forging kunye ne-rotary forging isetyenziswa kakhulu, kwaye izixhobo zithunyelwa kakhulu kumazwe angaphandle. I-radial forging iqhelekile kwizixhobo zenkampani ye-FELLS, ngelixa ukuguqulwa kwe-rotary kufana nezixhobo zenkampani ye-GFM. Ukubunjwa kweRadial forging ngokuqhelekileyo kuphunyezwa ngokusebenzisa izando ezine okanye ngaphezulu ezilinganayo kwi-frequency engaphezu kwama-240 imivumbo ngomzuzu ukuphumeza uguquko oluncinci lwetyhubhu engenanto kwaye ethe ngqo engenanto. Ukubunjwa kweRotary yinkqubo yokulungelelanisa ngokulinganayo iintloko zeehamile ezininzi kwicala elijikelezayo lebhili. Intloko yehamile ijikeleza i-axis ngelixa isenza i-radial high-frequency forging on workpiece, ukunciphisa ubungakanani be-cross-sectional ye-billet kunye nokwandisa i-axially ukufumana i-workpiece. Xa kuthelekiswa neeshafti zesiqhelo eziqinileyo, iindleko zokwenziwa kweeshafti ezihlanganisiweyo ezenziweyo ziya kunyuka malunga ne-20%, kodwa ubunzima beeshafti zeemoto buya kuncitshiswa ngokubanzi ngama-30-35%.

Ixesha lokuposa: Sep-15-2023