1. Isingeniso kwiiMoto zoMbane

Injini yombane sisixhobo esiguqula amandla ombane abe ngamandla omatshini. Isebenzisa ikhoyili yamandla (okt ukujikoza kwe-stator) ukuvelisa umhlaba ojikelezayo wemagnethi kwaye usebenze kwirotha (efana nekheji ye-squirrel evaliweyo isakhelo se-aluminiyam) ukwenza itorque ejikelezayo yemagneto.

Iinjini zombane zahlulwe kwiinjini ze-DC kunye neenjini ze-AC ngokwemithombo eyahlukeneyo yamandla esetyenziswayo. Uninzi lweenjini ezikwinkqubo yamandla ziinjini ze-AC, ezinokuthi zibe ziimotor ezihambelanayo okanye iimotor ezilinganayo (isantya sombane we-stator magnetic field asigcini isantya esihambelanayo kunye nesantya sokujikeleza kwerotor).

Imoto yombane ikakhulu iqulathe isitator kunye nerotor, kwaye isalathiso samandla asebenza kucingo olunamandla kwindawo yamagnetic inxulumene nesalathiso sangoku kunye nesalathiso somgca wokungeniswa kwamagnetic (ulwalathiso lwemagnetic field). Umgaqo osebenzayo wemoto yombane yimpembelelo yentsimi yamagnetic kumandla asebenzayo ngoku, okwenza ukuba i-motor ijikeleze.

2. Ukwahlulwa kweenjini zombane

① Ukuhlelwa ngokusebenza kombane

Ngokwemithombo eyahlukeneyo yokusebenza yamandla eenjini zombane, zinokwahlulwa zibe ziinjini zeDC kunye neenjini zeAC. Iimotor ze-AC nazo zohlulwe zibe ziimotor ezinenqanaba elinye kunye nenqanaba lesithathu.

② Ukuhlelwa ngokwesakhiwo kunye nomgaqo wokusebenza

Iimotor zombane zinokwahlulwa zibe ziimotor zeDC, iimotor ezilinganayo, kunye neemotor ezihambelanayo ngokobume bazo kunye nomgaqo wokusebenza. Iimotor ze-synchronous zinokwahlulwa zibe ziimotor ze-synchronous zemagnethi ezisisigxina, iimotor ezi-synchronous zokungafuni, kunye ne-hysteresis synchronous motors. Iinjini zeAsynchronous zinokwahlulwa zibe ziimotor induction kunye neemotor AC commutator. Iimotor zokungeniswa zikwahlulahlulwe ngokwamanqanaba amathathu asynchronous motors kunye neshaded pole asynchronous motors. Iinjini zokuhambisa i-AC zikwahlulwe ngokwenqanaba elinye leemoto ezichulumancisayo, iimoto ezineenjongo ezimbini ze-AC DC, kunye neenjini ezilandulayo.

③ Ihlelwa ngokwendlela yokuqalisa kunye nokusebenza

Iimotor zombane zinokwahlulwa zibe yi-capacitor eqalwe kwinqanaba elinye leemotor ezilinganayo, i-capacitor esebenza isigaba esinye semotor asynchronous, i-capacitor iqale inqanaba elinye lemotor ye-asynchronous, kunye nesigaba sokwahlulwa kwenqanaba elinye leemotor ezilinganayo ngokweendlela zazo zokuqala kunye nokusebenza.

④ Ukuhlelwa ngokwenjongo

Iinjini zombane zinokwahlulwa zibe ziinjini zokuqhuba kunye nokulawula iimotor ngokwenjongo yazo.

Iinjini zombane zokuqhuba zahlulwa kwakhona zibe zizixhobo zombane (kuquka ukubhola, ukupolisha, ukupolisha, ukutyibilika, ukusika nokwandisa izixhobo), iimotor zombane zezixhobo zendlu (kuquka oomatshini bokuhlamba, iifeni zombane, izikhenkcezisi, izixhobo zomoya, iirekhoda, izishicileli zevidiyo, Izidlali zeDVD, izicoci zokucoca umbane, iikhamera, izivutheli zombane, iishaver zombane, njl. njl.), kunye nezinye izixhobo zoomatshini abancinci ngokubanzi (kubandakanywa izixhobo zoomatshini abahlukeneyo abancinci, oomatshini abancinci, izixhobo zonyango, izixhobo zombane, njl.njl.).

Iinjini zokulawula zahlulwe ngakumbi kwiimotor ezinyathelayo kunye neenjini ze-servo.

⑤ Ukuhlelwa ngesakhiwo se-rotor

Ngokwesakhiwo se-rotor, iimotor zombane zinokwahlulwa zibe ziimotor induction cage (ezaziwa ngaphambili njenge-squirrel cage asynchronous motors) kunye ne-rotor induction motors (eyayisaziwa njengeemotor ze-asynchronous motors).

⑥ Yahlelwa ngesantya sokusebenza

Iinjini zombane zinokwahlulwa zibe ziinjini ezinesantya esiphezulu, iimotor ezinesantya esiphantsi, iimotor ezinesantya esingaguqukiyo, kunye neemotor eziguquguqukayo ngokwesantya sokusebenza kwazo.

⑦ Ukuhlelwa ngokwefomu yokukhusela

a. Vula uhlobo (njenge IP11, IP22).

Ngaphandle kwesakhiwo senkxaso esiyimfuneko, i-motor ayinalo ukhuseleko olukhethekileyo kwiindawo ezijikelezayo kunye neziphilayo.

b. Uhlobo oluvaliweyo (olufana ne-IP44, IP54).

Iindawo ezijikelezayo kunye neziphilayo ngaphakathi kwecasing yemoto zidinga ukhuseleko oluyimfuneko ngoomatshini ukuthintela ukudibana ngengozi, kodwa ayithinteli kakhulu ukungena komoya. Iimoto ezikhuselayo zohlulwe zibe zintlobo zilandelayo ngokweendlela zazo ezahlukeneyo zokungenisa umoya kunye nezakhiwo zokukhusela.

ⓐ Uhlobo lwekhava yomnatha.

Ukuvuleka komoya wemoto kugqunywe ngezigqubuthelo ezinemingxuma ukunqanda iindawo ezijikelezayo neziphilayo zemoto ukuba zingadibani nezinto zangaphandle.

ⓑ Ukumelana nokuthontsiza.

Ulwakhiwo lwe-motor vent lunokuthintela ulwelo oluwa ngokuthe nkqo okanye izinto eziqinileyo ukuba zingene ngqo ngaphakathi ngaphakathi kwinjini.

ⓒ Ubungqina bokutshiza.

Ulwakhiwo lwe-motor vent inokuthintela ulwelo okanye izinto eziqinileyo ekungeneni ngaphakathi kwemoto kulo naliphi na icala ngaphakathi koluhlu oluthe nkqo lwe-engile ye-100 °.

ⓓ Ivaliwe.

Ukwakhiwa kwe-motor casing kunokuthintela ukutshintshiselana simahla komoya ngaphakathi nangaphandle kwe-casing, kodwa ayifuni ukutywinwa ngokupheleleyo.

ⓔ Ukungangeni manzi.

Ukwakhiwa kwe-motor casing kunokuthintela amanzi ngoxinzelelo oluthile lokungena ngaphakathi kwemoto.

ⓕ Ukungangeni manzi.

Xa i-motor intywiliselwa emanzini, ubume be-motor casing inokuthintela amanzi ukuba angene ngaphakathi kwi-motor.

ⓖ Isimbo sokuntywila.

Imoto yombane inokusebenza emanzini ixesha elide phantsi koxinzelelo lwamanzi olulinganisiweyo.

ⓗ Ubungqina bokudubula.

Isakhiwo se-motor casing sanele ukukhusela ukuqhuma kwegesi ngaphakathi kwi-motor ukuba ingadluliswa ngaphandle kwe-motor, okubangela ukuqhuma kwegesi evuthayo ngaphandle kwemoto. I-akhawunti esemthethweni "I-Mechanical Engineering Literature", isikhululo segesi sobunjineli!

⑧ Ihlelwa ngokungena komoya kunye neendlela zokupholisa

a. Ukuzipholisa.

Iinjini zombane zithembele kuphela kwimitha engaphezulu kunye nokuhamba komoya kwendalo ukupholisa.

b. Ifeni ezipholileyo.

Imoto yombane iqhutywa yifeni enika umoya opholileyo ukupholisa umphezulu okanye ngaphakathi kwemoto.

c. Waphola ifeni.

I-fan enikezela umoya opholileyo ayiqhutywa yimoto yombane ngokwayo, kodwa iqhutywa ngokuzimeleyo.

d. Uhlobo lwemibhobho yokungenisa umoya.

Umoya opholileyo awungeniswa ngokuthe ngqo okanye ukhutshwe ngaphandle kwemoto okanye ngaphakathi kwenjini, kodwa uyangeniswa okanye ukhutshwe kwi-motor ngokusebenzisa imibhobho. Iifeni zokungena komoya wombhobho zinokupholiswa yifeni ngokwayo okanye enye ifeni ipholiswe.

e. Ukupholisa ulwelo.

Iinjini zombane zipholiswa ngolwelo.

f. Ukupholisa igesi yesekethe evaliweyo.

Umjikelezo ophakathi wokupholisa i-motor kwisiphaluka esivaliweyo esibandakanya i-motor kunye ne-cooler. Indawo yokupholisa ifunxa ubushushu xa udlula kwinjini kwaye ikhuphe ubushushu xa udlula kwisipholile.

g. Ukupholisa umphezulu kunye nokupholisa kwangaphakathi.

Isiphakathi sokupholisa esingadluliyo ngaphakathi kwi-motor conductor ibizwa ngokuba yi-surface cooling, ngelixa indawo yokupholisa edlula ngaphakathi kwi-motor conductor ibizwa ngokuba yi-internal cooling.

⑨ Ukuhlelwa ngokwefomu yofakelo lwesakhiwo

Ifom yokufakela iinjini zombane ngokuqhelekileyo imelwe ngeekhowudi.

Ikhowudi imelwe sisishunqulelo se-IM sofakelo lwamazwe ngamazwe,

Unobumba wokuqala kwi-IM umele uhlobo lofakelo lwekhowudi, u-B umele ufakelo oluthe tye, kwaye u-V umele ufakelo oluthe nkqo;

Idijithi yesibini imele ikhowudi yefitsha, emelwe ngamanani esiArabhu.

⑩ Ukuhlelwa ngokwenqanaba lokugquma

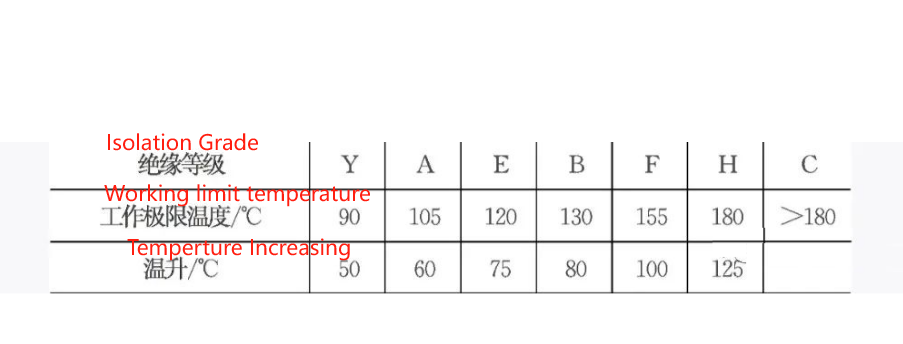

I-A-level, i-E-level, i-B-level, i-F-level, i-H-level, i-level. Ukuhlelwa kwenqanaba lokugquma kweenjini kuboniswe kwitheyibhile engezantsi.

⑪ Ihlelwe ngokweeyure zokusebenza ezirethiweyo

Inkqubo yokusebenza eqhubekayo, ephakathi, kunye neyexesha elifutshane.

Inkqubo yoMsebenzi oQhubekekayo (SI). I-motor iqinisekisa ukusebenza kwexesha elide phantsi kwexabiso elilinganisiweyo elichazwe kwi-nameplate.

Ixesha elifutshane lokusebenza iiyure (S2). I-motor inokusebenza kuphela ixesha elilinganiselweyo phantsi kwexabiso elilinganisiweyo elichazwe kwi-nameplate. Kukho iintlobo ezine zemigangatho yexesha lokusebenza kwexesha elifutshane: 10min, 30min, 60min, kunye ne-90min.

Inkqubo yokusebenza yethutyana (S3). I-motor ingasetyenziselwa kuphela ngokukhawuleza kwaye ngamaxesha phantsi kwexabiso elilinganisiweyo elichazwe kwi-nameplate, echazwe njengepesenti yemizuzu ye-10 kumjikelo ngamnye. Umzekelo, FC=25%; Phakathi kwabo, i-S4 ukuya kwi-S10 yeyohlukeneyo yeenkqubo zokusebenza ezisebenzayo phantsi kweemeko ezahlukeneyo.

9.2.3 Iimpazamo eziqhelekileyo zeenjini zombane

Iinjini zombane zihlala zidibana neempazamo ezahlukeneyo ngexesha lokusebenza kwexesha elide.

Ukuba ukuhanjiswa kwe-torque phakathi kwekhonkco kunye ne-reducer kukhulu, umngxuma wokudibanisa kwi-flange surface ubonisa ukugqithiswa okukhulu, okwandisa i-gap efanelekileyo yokudibanisa kwaye kukhokelela ekugqithiseni i-torque engazinzanga; Ukunxiba kwendawo yokuthwala okubangelwa ngumonakalo kwi-motor shaft bear; Nxiba phakathi kweentloko ze-shaft kunye neendlela ezingundoqo, njl. Emva kokuvela kweengxaki ezinjalo, iindlela zemveli zigxininisa ukulungiswa kwe-welding okanye i-machining emva kokufakwa kwebrashi, kodwa zombini zineengxaki ezithile.

Uxinzelelo lwe-thermal oluveliswa yi-welding yokulungiswa kweqondo lokushisa eliphezulu alukwazi ukupheliswa ngokupheleleyo, olulungele ukugoba okanye ukuphuka; Nangona kunjalo, i-brush plating inqunyelwe ngobunzima bengubo kwaye ijwayele ukuxubha, kwaye zombini iindlela zisebenzisa isinyithi ukulungisa isinyithi, esingenako ukutshintsha ubudlelwane "obunzima kunzima". Ngaphantsi kwesenzo esidibeneyo samandla ahlukeneyo, kuya kuphinda kubangele ukugqoka kwakhona.

Amazwe aseNtshona anamhlanje ahlala esebenzisa imathiriyeli edibeneyo yepolymer njengeendlela zokulungisa ukujongana nale miba. Ukusetyenziswa kwezixhobo zepolymer zokulungiswa akuchaphazeli i-welding yoxinzelelo lwe-thermal, kwaye ubukhulu bokulungisa abukhawulelwanga. Kwangaxeshanye, izinto zetsimbi kwimveliso azinakho ukuguquguquka kokufunxa impembelelo kunye nokungcangcazela kwesixhobo, kunqande ukuphinda kunxitywe, kwaye kwandise ubomi benkonzo yamacandelo ezixhobo, ukonga ixesha elininzi lokuphumla kumashishini kunye ukudala ixabiso elikhulu kwezoqoqosho.

(1) Into ephosakeleyo: I-motor ayikwazi ukuqala emva kokuba ixhunyiwe

Izizathu kunye neendlela zokuphatha zezi zilandelayo.

① Impazamo yokuvala i-Stator-jonga i-wiring kwaye ulungise impazamo.

② Vula isiphaluka kwi-stator winding, i-short circuiting grounding, isiphaluka esivulekileyo kwi-winding ye-rotor motor yesilonda-chonga indawo yephutha kwaye uyisuse.

③ Umthwalo ogqithisileyo okanye indlela yothumelo oluxingileyo - jonga indlela yothumelo kunye nomthwalo.

④ Vula isiphaluka kwisiphaluka se-rotor yesilonda se-rotor motor (uqhagamshelwano olubi phakathi kwe-brush kunye ne-slip ring, isiphaluka esivulekileyo kwi-rheostat, uqhagamshelwano olubi kwi-lead, njl.) -chonga indawo yesiphaluka evulekile kwaye uyilungise.

⑤ Umbane wombane uphantsi kakhulu - khangela isizathu kwaye uyisuse.

⑥ Ukulahleka kwesigaba sokunikezelwa kwamandla - khangela isiphaluka kwaye ubuyisele isigaba sesithathu.

(2) Imeko yempazamo: Ubushushu beMoto bonyuka kakhulu okanye ukutshaya

Izizathu kunye neendlela zokuphatha zezi zilandelayo.

① Ukulayisha ngaphezulu okanye kuqalwe rhoqo kakhulu - nciphisa umthwalo kwaye unciphise inani lokuqalisa.

② Ukulahleka kwesigaba ngexesha lokusebenza - khangela isiphaluka kwaye ubuyisele isigaba sesithathu.

③ Impazamo yokuvala i-stator-jonga i-wiring kwaye uyilungise.

④ I-stator winding isekelwe, kwaye kukho isiphaluka esifutshane phakathi kokujika okanye izigaba - chonga isiseko okanye indawo yesiphaluka esifutshane kwaye uyilungise.

⑤ I-Cage rotor yaphukile - buyisela i-rotor.

⑥ Isigaba esilahlekileyo sokujikeleza kwe-rotor yenxeba-chonga indawo yempazamo kwaye uyilungise.

⑦ Ukuxubana phakathi kwe-stator kunye ne-rotor - Khangela iibheringi kunye ne-rotor ye-deformation, ukulungiswa okanye ukubuyisela.

⑧ Ukungena komoya okungalunganga - khangela ukuba umoya awuphazamiseki.

⑨ I-voltage iphezulu kakhulu okanye iphantsi kakhulu - Jonga unobangela kwaye uyisuse.

(3) Impazamo yempazamo: Ukungcangcazela okugqithisileyo kwemoto

Izizathu kunye neendlela zokuphatha zezi zilandelayo.

① I-rotor engalinganiyo - ibhalansi yokulinganisa.

② I-pulley engalinganiyo okanye isandiso se-shaft egobileyo - khangela kwaye ulungise.

③ I-motor ayihambelani ne-axis yomthwalo - khangela kwaye ulungise i-axis yeyunithi.

④ Ufakelo olungafanelekanga lwe-motor - khangela ukufakwa kunye nezikrufu zesiseko.

⑤ Umthwalo ogqithisileyo ngesiquphe - nciphisa umthwalo.

(4)Impazamo: Isandi esingaqhelekanga ngexesha lokusebenza

Izizathu kunye neendlela zokuphatha zezi zilandelayo.

① Ukungquzulana phakathi kwe-stator kunye ne-rotor - Jonga iibheringi kunye ne-rotor ye-deformation, ukulungiswa okanye ukubuyisela.

② Iibheringi ezonakalisiweyo okanye ezifakwe kakubi - buyisela kwaye ucoce iibheringi.

③ Umsebenzi wokulahleka kwenqanaba leMotor - jonga indawo evulekileyo yesekethe kwaye uyilungise.

④ Ukungqubana kweblade necasing - jonga kwaye uphelise iimpazamo.

(5) Into ephosakeleyo: Isantya semoto siphantsi kakhulu xa siphantsi komthwalo

Izizathu kunye neendlela zokuphatha zezi zilandelayo.

① Amandla ombane ombane aphantsi kakhulu - jonga umbane wombane.

② Umthwalo ogqithisileyo - khangela umthwalo.

③ I-Cage rotor ejikelezayo eyaphukileyo - buyisela i-rotor.

④ Uqhagamshelwano olubi okanye olunqanyuliweyo lwesinye isigaba seqela locingo lwe-rotor - khangela uxinzelelo lwebrashi, uqhagamshelwano phakathi kwebrashi kunye ne-ring ring, kunye ne-rotor winding.

(6) Impazamo: I-motor casing iyaphila

Izizathu kunye neendlela zokuphatha zezi zilandelayo.

① Umgangatho ophantsi okanye ukuxhathisa okuphezulu - Qhagamshela ucingo lomhlaba ngokwemigaqo yokuphelisa iimpazamo ezimbi.

② Ii-windings zimanzi - zifumana unyango lokomisa.

③ Ukonakala kwe-insulation, ukungqubana okukhokelayo - Gxuma ipeyinti ukulungisa ukugquma, ukudibanisa kwakhona iinkokeli. 9.2.4 Iinkqubo zokusebenza kweemoto

① Phambi kokuqhaqha, sebenzisa umoya ocinezelweyo ukuvuthela uthuli phezu kwemoto kwaye uyisule icoceke.

② Khetha indawo ekusetyenzwa kuyo ukuze udityaniswe neemoto kwaye ucoce imo engqongileyo yendawo.

③ Uqhelene neempawu zesakhiwo kunye nokugcinwa kweemfuno zobugcisa beemoto zombane.

④ Lungisa izixhobo eziyimfuneko (kubandakanywa izixhobo ezikhethekileyo) kunye nezixhobo zokuqhaqha.

⑤ Ukuze uqonde ngakumbi iziphene ekusebenzeni kwemoto, uvavanyo lokuhlola lunokuqhutywa ngaphambi kokuchithwa ukuba iimeko zivuma. Ukuza kuthi ga ngoku, i-motor ivavanywa ngomthwalo, kwaye ubushushu, isandi, ukungcangcazela, kunye nezinye iimeko zenxalenye nganye yemoto zijongwa ngokweenkcukacha. I-voltage, okwangoku, isantya, njl njl. Emva koko, umthwalo unqanyuliwe kwaye uvavanyo oluhlukeneyo lokungabikho komthwalo lwenziwa ukulinganisa ukungabikho komthwalo wangoku kunye nokulahlekelwa komthwalo, kunye neerekhodi zenziwe. I-akhawunti esemthethweni "I-Mechanical Engineering Literature", isikhululo segesi sobunjineli!

⑥ Sika unikezelo lombane, susa iingcingo zangaphandle zenjini, kwaye ugcine iirekhodi.

⑦ Khetha i-voltage megohmmeter efanelekileyo ukuvavanya ukuxhathisa kwe-insulation ye-motor. Ukuze uthelekise amaxabiso okumelana nobushushu obulinganisiweyo ngexesha logcino lokugqibela ukumisela umkhwa wokutshintsha kogqume kunye nemo yokugquma i-motor, amaxabiso okumelana nobushushu obulinganiswe kumaqondo obushushu ahlukeneyo kufuneka aguqulelwe kubushushu obufanayo, ngokuqhelekileyo aguqulelwe kuma-75 ℃.

⑧ Uvavanya umlinganiselo wokufunxa K. Xa umlinganiselo wokufunxa K> 1.33, ubonisa ukuba ukugquma kwemoto akuchatshazelwanga bubumanzi okanye iqondo lokufuma alibi kakhulu. Ukuze uthelekise idatha yangaphambili, kuyafuneka kwakhona ukuguqula umlinganiselo wokufunxa ulinganiswe nakweyiphi na iqondo lokushisa kwiqondo lokushisa elifanayo.

9.2.5 Ukugcinwa nokulungiswa kweenjini zombane

Xa i-motor isebenza okanye ingasebenzi kakuhle, kukho iindlela ezine zokuthintela kunye nokuphelisa iimpazamo ngexesha elifanelekileyo, ezizezi, ukujonga, ukuphulaphula, ukuvumba, kunye nokuchukumisa, ukuqinisekisa ukusebenza ngokukhuselekileyo kwemoto.

(1) Jonga

Qwalasela ukuba kukho naziphi na izinto ezingaqhelekanga ngexesha lokusebenza kwemoto, ezibonakaliswa ikakhulu kwezi meko zilandelayo.

① Xa i-stator winding imfutshane, umsi unokubonwa kwi-motor.

② Xa i-motor igxininiswe kakhulu okanye iphelile kwisigaba, isantya siya kuthotha kwaye kuya kuba nesandi esinzima "sokubetha".

③ Xa injini ibaleka ngokuqhelekileyo, kodwa ime ngequbuliso, iintlantsi zinokuvela kuqhagamshelo olukhululekileyo; Isenzeko sokuvuthelwa kwefuse okanye icandelo lixinge.

④ Ukuba i-motor ishukuma ngamandla, inokuba kungenxa yokuxinana kwesixhobo sothumelo, ukulungiswa kakubi kwemoto, iibholiti zesiseko, njl.

⑤ Ukuba kukho ukuguquguquka kwebala, amabala okutsha, kunye namabala omsi kwiindawo ezidityanisiweyo zangaphakathi kunye noqhagamshelo lwemoto, oko kubonisa ukuba kunokubakho ukufudumeza kwendawo, ukudibana okulambathayo kwiikondaktara ezidityanisiweyo, okanye amajiko-jiko atshileyo.

(2) Phulaphula

I-motor kufuneka ikhuphe isandi esifanayo kunye nokukhanya "okukhwaza" ngexesha lokusebenza okuqhelekileyo, ngaphandle kwengxolo okanye izandi ezikhethekileyo. Ukuba kukhutshwa ingxolo eninzi kakhulu, kubandakanywa ingxolo ye-electromagnetic, ingxolo, ingxolo yokuphuma komoya, ingxolo yomatshini wokukhuhlana, njl.

① Ngengxolo ye-electromagnetic, ukuba injini ikhupha isandi esikhulu nesinzima, kunokubakho izizathu ezininzi.

a. I-gap yomoya phakathi kwe-stator kunye ne-rotor ayilingani, kwaye isandi siguquguquka ukusuka phezulu ukuya phezulu kunye nexesha elifanayo lekhefu phakathi kwezandi eziphakamileyo neziphantsi. Oku kubangelwa ukuthwala ukuthwala, okubangela ukuba i-stator kunye ne-rotor ingabikho.

b. Inqanaba lesithathu langoku alilingani. Oku kungenxa yokumisa okungalunganga, isiphaluka esifutshane, okanye uqhagamshelwano olubi lwesigaba sesithathu sokujika. Ukuba isandi sinzima kakhulu, kubonisa ukuba i-motor ilayishwe kakhulu okanye iphelile kwisigaba.

c. Undoqo wentsimbi. Ukungcangcazela kwenjini ngexesha lokusebenza kubangela ukuba iibholithi zokulungisa zombindi wentsimbi zikhululeke, nto leyo ebangela ukuba i-silicon yentsimbi yombindi wentsimbi ikhulule kwaye ikhuphe ingxolo.

② Ukuthwala ingxolo, kufuneka ibekwe iliso rhoqo ngexesha lokusebenza kwemoto. Indlela yokubeka iliso kukucinezela isiphelo esinye se-screwdriver kwindawo yokunyuka ye-bearing, kwaye esinye isiphelo sisondele kwindlebe ukuva isandi sokuthwala ubaleka. Ukuba ukuthwala kusebenza ngokuqhelekileyo, isandi salo siya kuba sisandi esiqhubekayo nesincinci "sokurhwashaza", ngaphandle kokuguquguquka kobude okanye isandi sentsimbi. Ukuba ezi zandi zilandelayo ziyenzeka, kuthathwa njengento engaqhelekanga.

a. Kukho isandi "sokubetha" xa i-bearing iqhuba, isandi sentsimbi yentsimbi, ngokuqhelekileyo ibangelwa ukungabikho kweoli kwi-bearing. Ukuthwala kufuneka kuhlakazwe kwaye kongezwe ngexabiso elifanelekileyo legrisi yokuthambisa.

b. Ukuba kukho isandi esithi "creaking", sisandi esenziwa xa ibhola ijikeleza, ngokuqhelekileyo ibangelwa ukomisa igrisi yokuthambisa okanye ukungabikho kweoli. Umlinganiselo ofanelekileyo wegrisi unokongezwa.

c. Ukuba kukho isandi "sokuchofoza" okanye "i-creaking", sisandi esiveliswa yintshukumo engaqhelekanga yebhola kwi-bearing, ebangelwa umonakalo webhola kwi-bearing okanye ukusetyenziswa kwexesha elide le-motor. , kunye nokomiswa kwegrisi yokuthambisa.

③ Ukuba indlela yothumelo kunye nesixhobo esiqhutywayo zikhupha ngokuqhubekayo kunezandi eziguquguqukayo, zinokuphathwa ngezi ndlela zilandelayo.

a. Izandi zexesha elithi "popping" zibangelwa ngamabhanti angalinganiyo.

b. Isandi sexesha "sokubetha" sibangelwa ukudibanisa okuxekethileyo okanye i-pulley phakathi kwee-shafts, kunye nezitshixo ezigugileyo okanye izitshixo.

c. Isandi sokungqubana esingalinganiyo sibangelwa ziincakuba zomoya ezingqubana nesigqubuthelo sefeni.

(3) Ukujoja

Ngokuphunga ivumba lemoto, iimpazamo zinokubonwa kwaye zithintelwe. Ukuba iphunga elikhethekileyo lepeyinti lifunyenwe, libonisa ukuba ukushisa kwangaphakathi kwemoto kuphezulu kakhulu; Ukuba ivumba elitshisayo elivuthayo okanye elivuthayo lifunyenwe, linokuthi libe ngenxa yokuphuka kwe-insulation layer okanye ukutshiswa kwe-winding.

(4) Ukuchukumisa

Ukuchukumisa ubushushu bezinye iinxalenye zemoto kunokumisela unobangela wokungasebenzi kakuhle. Ukuqinisekisa ukhuseleko, umva wesandla kufuneka usetyenziswe ukubamba iindawo ezijikelezayo ze-motor casing kunye neebheringi xa ubamba. Ukuba kufunyenwe ukungaqhelekanga kobushushu, kunokubakho izizathu ezininzi.

① Ukungena komoya kubi. Okufana ne-fan detachment, i-blocked ventilation ducts, njl.

② Ukugcwala. Ukubangela ukugqithisa ngokugqithisileyo kunye nokushisa kwe-stator winding.

③ Isiphaluka esifutshane phakathi kwe-stator windings okanye isigaba sesithathu sokungalingani kwangoku.

④ Ukuqala rhoqo okanye ukuqhobosha.

⑤ Ukuba iqondo lokushisa elijikeleze i-bearing liphezulu kakhulu, linokubangelwa ukuthwala umonakalo okanye ukungabikho kweoli.

Ixesha lokuposa: Oct-06-2023