Izinto ezichaphazela ukusetyenziswa kwentsimbi esisiseko

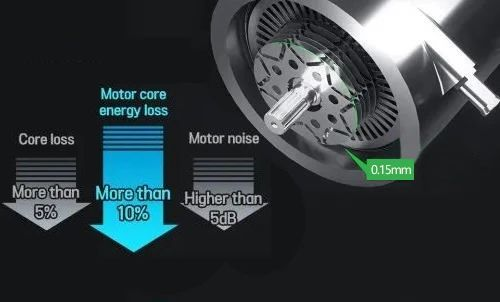

Ukuhlalutya ingxaki, kuqala kufuneka sazi iingcamango ezisisiseko, eziya kusinceda siqonde. Okokuqala, kufuneka sazi iikhonsepthi ezimbini. Enye i-alternating magnetization, leyo, ukuyibeka ngokulula, ivela kwintsimbi yentsimbi ye-transformer kunye ne-stator okanye i-rotor amazinyo emoto; Enye yipropati ejikelezayo ye-magnetization, eyenziwa yi-stator okanye idyokhwe ye-rotor ye-motor. Kukho amanqaku amaninzi aqala ukusuka kumanqaku amabini kwaye abale ilahleko yentsimbi yemoto ngokusekelwe kwiimpawu ezahlukeneyo ngokwendlela yesisombululo esingentla. Iimvavanyo zibonise ukuba amaphepha ensimbi e-silicon abonisa le nto ilandelayo phantsi kwemagnethi yeepropathi ezimbini:

Xa uxinaniso lwemagnethi lungaphantsi kwe-1.7 Tesla, ilahleko ye-hysteresis ebangelwa yimagnetization ejikelezayo inkulu kunoko kubangelwa kukutshintshana kwemagneti; Xa iphezulu kune-1.7 Tesla, okuchaseneyo kuyinyaniso. Uxinaniso lwemagnethi eguquguqukayo yedyokhwe yemoto ngokubanzi luphakathi kwe-1.0 kunye ne-1.5 Tesla, kwaye ilahleko ejikelezayo yemagnetization hysteresis imalunga ne-45 ukuya kuma-65% enkulu kunokulahleka kwemagnetization hysteresis.

Ngokuqinisekileyo, ezi zigqibo zingasentla zikwasetyenziswa, kwaye andizange ndiqinisekise ngokwam ngokusebenza. Ukongezelela, xa i-magnetic field kwi-iron core itshintsha, i-current induced kuyo, ebizwa ngokuba yi-eddy current, kwaye ilahleko ebangelwa yiyo ibizwa ngokuba yi-eddy yangoku ilahleko. Ukuze kuncitshiswe ilahleko ye-eddy yangoku, i-motor iron core ayinakwenziwa ukuba ibe yibhloko epheleleyo, kwaye ibekwe nge-axially ngamashiti entsimbi afakwe i-insulated ukuthintela ukuhamba kwemisinga eddy. Ifomula yokubala ethile yokusetyenziswa kwentsimbi ayiyi kuba nzima apha. Ifomula esisiseko kunye nokubaluleka kokubala kokusetyenziswa kwentsimbi ye-Baidu kuya kucaca kakhulu. Oku kulandelayo lucazululo lwemiba eliqela ephambili echaphazela ukusetyenziswa kwethu kwentsimbi, ukuze wonke umntu akwazi ukuya phambili okanye umva afumane ingxaki kwizicelo zobunjineli ezisebenzayo.

Emva kokuxoxa ngoku ngasentla, kutheni ukwenziwa kwesitampu kuchaphazela ukusetyenziswa kwentsimbi? Iimpawu zenkqubo yokugqobhoza ubukhulu becala zixhomekeke kwiimilo ezahlukeneyo zoomatshini bokugqobhoza, kwaye zimisele imowudi yokucheba ehambelanayo kunye nenqanaba loxinzelelo ngokweemfuno zeentlobo ezahlukeneyo zemingxuma kunye nemijelo, ngaloo ndlela iqinisekisa iimeko zemimandla yoxinzelelo olungenzulu ejikeleze iperiphery ye-lamination. Ngenxa yobudlelwane phakathi kobunzulu kunye nokumila, kudla ngokuchatshazelwa zii-engile ezibukhali, ukuya kuthi ga kwinqanaba lokuba amanqanaba aphezulu oxinzelelo anokubangela ilahleko enkulu yentsimbi kwiindawo zoxinzelelo olungenzulu, ngakumbi kwimiphetho yokucheba emide ngokwentelekiso ngaphakathi koluhlu lwe-lamination. Ngokukodwa, iyenzeka ikakhulu kwingingqi ye-alveolar, ehlala igxile kuphando lweyona nkqubo yophando. Ilahleko ephantsi ye-silicon sheets yentsimbi idla ngokumiselwa ngobungakanani beenkozo ezinkulu. Impembelelo inokubangela i-synthetic burrs kunye nokukrazula i-shear kumda ophantsi weshidi, kwaye i-angle yempembelelo ingaba nefuthe elibalulekileyo kubukhulu be-burrs kunye neendawo zokuguqulwa. Ukuba ummandla woxinzelelo oluphezulu unwenwela ecaleni kwendawo yoguquko oluphakathi ukuya ngaphakathi kwesixhobo, ubume benkozo kwezi ndawo ngokuqinisekileyo luya kuthi lwenze utshintsho oluhambelanayo, lujijelwe okanye luqhekeke, kwaye ukwanda okugqithisileyo komda kuya kwenzeka ecaleni kwendlela yokukrazula. Ngeli xesha, ukuxinana komda wengqolowa kwindawo yoxinzelelo kwicala lokucheba ngokuqinisekileyo kuya kwanda, okukhokelela ekunyukeni okuhambelanayo kwilahleko yentsimbi ngaphakathi kwingingqi. Ngoko ke, ngeli nqanaba, izinto eziphathekayo kwindawo yoxinzelelo zinokuthathwa njengezinto ezilahlekileyo eziphezulu eziwela phezu kwe-lamination eqhelekileyo ecaleni kwempembelelo yempembelelo. Ngale ndlela, ukugcinwa kwangempela kwezinto ezinqamlekileyo kunokumiselwa, kwaye ukulahleka kwangempela kwempembelelo yempembelelo kunokugqitywa ngakumbi ngokusebenzisa imodeli yokulahlekelwa kwentsimbi.

1.Impembelelo yeNkqubo yokuHlomela kwilahleko yentsimbi

Iimeko zempembelelo yelahleko yentsimbi ikhona ikakhulu kwinkalo yamaphepha ensimbi ye-silicon, kwaye uxinzelelo lomatshini kunye nobushushu luya kuchaphazela amaphepha ensimbi e-silicon kunye notshintsho kwiimpawu zabo zokwenyani. Uxinzelelo olongezelelweyo lomatshini luya kukhokelela ekutshintsheni ilahleko yentsimbi. Kwangaxeshanye, ukunyuka okuqhubekayo kobushushu bangaphakathi kwimoto kuya kukhuthaza ukwenzeka kweengxaki zokulahleka kwentsimbi. Ukuthatha amanyathelo asebenzayo okususa uxinzelelo olongezelelweyo lomatshini kuya kuba nefuthe elihle ekunciphiseni ilahleko yentsimbi ngaphakathi kwinjini.

2.Izizathu zelahleko egqithisileyo kwiinkqubo zokuvelisa

Amashidi ensimbi ye-silicon, njengeyona nto iphambili yamagnetic yeemoto, inefuthe elibalulekileyo ekusebenzeni kwemoto ngenxa yokuthotyelwa kwazo kwiimfuno zoyilo. Ukongezelela, ukusebenza kwamaphepha ensimbi ye-silicon yebakala elifanayo kunokwahluka kubavelisi abahlukeneyo. Xa ukhetha izixhobo, kufuneka kwenziwe iinzame zokukhetha izinto ezivela kubavelisi bentsimbi ye-silicon elungileyo. Ngezantsi kukho izinto eziphambili eziye zachaphazela ukusetyenziswa kwentsimbi eziye zadibana nazo ngaphambili.

I-silicon sheet sheet ayizange ifakwe i-insulated okanye iphathwe ngokufanelekileyo. Olu hlobo lwengxaki lunokubonwa ngexesha lovavanyo lwamaphepha ensimbi ye-silicon, kodwa ayingabo bonke abavelisi beemoto abanale nto yokuvavanya, kwaye le ngxaki kaninzi ayiqatshelwa kakuhle ngabavelisi beemoto.

I-insulation eyonakele phakathi kwamaphepha okanye iisekethe ezimfutshane phakathi kwamaphepha. Olu hlobo lwengxaki lwenzeka ngexesha lokwenziwa kwenkqubo yentsimbi. Ukuba uxinzelelo ngexesha le-lamination yentsimbi yentsimbi iphezulu kakhulu, ibangela umonakalo kwi-insulation phakathi kwamaphepha; Okanye ukuba i-burrs inkulu kakhulu emva kokubetha, inokususwa ngokupolisha, okubangela umonakalo omkhulu kwi-insulation of the punching surface; Emva kokuba i-iron core lamination igqityiwe, i-groove ayilulanga, kwaye indlela yokufakela isetyenziswe; Kungenjalo, ngenxa yezinto ezifana ne-stator engalinganiyo kunye nokungagxili phakathi kwe-stator bore kunye nomlebe wesihlalo somatshini, ukujika kungasetyenziselwa ukulungiswa. Ukusetyenziswa okuqhelekileyo kolu kuveliswa kweemoto kunye neenkqubo zokucubungula ngokwenene kunempembelelo ebalulekileyo ekusebenzeni kwemoto, ngakumbi ilahleko yentsimbi.

Xa usebenzisa iindlela ezinjengokutshisa okanye ukufudumeza ngombane ukuqhaqha i-winding, kunokubangela ukuba i-iron core igqithise, okubangelwa ukuhla kwe-conductivity magnetic kunye nomonakalo kwi-insulation phakathi kwamaphepha. Le ngxaki iyenzeka kakhulu ngexesha lokulungiswa kwe-winding kunye ne-motor ngexesha lemveliso kunye nenkqubo yokucubungula.

Ukupakisha i-welding kunye nezinye iinkqubo kunokubangela umonakalo kwi-insulation phakathi kwezitaki, ukwandisa ilahleko yangoku ye-eddy.

Ubunzima bentsimbi obunganelanga kunye nokudibanisa okungaphelelanga phakathi kwamaphepha. Isiphumo sokugqibela kukuba ubunzima bentsimbi yentsimbi abunelanga, kwaye umphumo ochanekileyo kukuba i-current idlula ukunyamezela, ngelixa kunokubakho ukuba ilahleko yentsimbi idlula umgangatho.

Umaleko kwiphepha lentsimbi yesilicon ungqingqwa kakhulu, nto leyo ebangela ukuba isekethe yemagnethi igcwale kakhulu. Ngeli xesha, ijika lobudlelwane phakathi kokungabikho komthwalo wangoku kunye ne-voltage igobe kakhulu. Oku kukwayinto ephambili kwimveliso kunye nenkqubo yokucubungula i-silicon sheet sheet.

Ngethuba lokuveliswa kunye nokucutshungulwa kweentsimbi zentsimbi, ukuqhelaniswa kweenkozo ze-silicon steel sheet punching kunye ne-shearing surface attachment kunokonakala, okukhokelela ekwandeni kwelahleko yentsimbi phantsi kwe-induction efanayo yamagnetic; Kwiimotor frequency frequency, ilahleko ezongezelelweyo zentsimbi ezibangelwa yi-harmonics kufuneka ziqwalaselwe; Lo ngumba omele uqwalaselwe ngokubanzi kwinkqubo yoyilo.

Ukongeza kwezi zinto zingentla, ixabiso loyilo lokulahleka kwentsimbi yemoto kufuneka lisekelwe kwimveliso eyiyo kunye nokusetyenzwa kombindi wentsimbi, kwaye zonke iinzame kufuneka zenziwe ukuqinisekisa ukuba ixabiso lethiyori lihambelana nelona xabiso. Iimpawu zeempawu ezibonelelwa ngababoneleli bezinto eziqhelekileyo zilinganiswa kusetyenziswa indlela ye-coil ye-Epstein yesikwere, kodwa ulwalathiso lwe-magnetization lwamacandelo ahlukeneyo kwi-motor yahlukile, kwaye le lahleko ekhethekileyo yentsimbi ejikelezayo ayinakuqwalaselwa ngoku. Oku kunokukhokelela kumanqanaba ahlukeneyo okungahambelani phakathi kwamaxabiso abaliweyo kunye nalinganisiweyo.

Iindlela zokunciphisa ilahleko yentsimbi kuyilo lobunjineli

Kukho iindlela ezininzi zokunciphisa ukusetyenziswa kwentsimbi kubunjineli, kwaye eyona nto ibalulekileyo kukulungelelanisa iyeza kwimeko. Ngokuqinisekileyo, akukhona nje malunga nokusetyenziswa kwentsimbi, kodwa kunye nezinye iilahleko. Eyona ndlela isisiseko kukwazi izizathu zokulahleka kwentsimbi ephezulu, njengoxinaniso oluphezulu lwemagnethi, amaza omoya aphezulu, okanye ukugcwala okugqithisileyo kwendawo. Ngokuqinisekileyo, ngendlela eqhelekileyo, kwelinye icala, kuyimfuneko ukusondela kwinyani ngokusondeleyo ukusuka kwicala lokulinganisa, kwaye ngakolunye uhlangothi, inkqubo idibene neteknoloji yokunciphisa ukusetyenziswa kwesinyithi esongezelelweyo. Eyona ndlela isetyenziswa ngokuqhelekileyo kukwandisa ukusetyenziswa kwe-silicone sheet sheets elungileyo, kwaye kungakhathaliseki ukuba yindleko, intsimbi ye-silicon ephezulu engenisiweyo inokukhethwa. Ewe, uphuhliso lobugcisa obutsha obuqhutywa ngamandla wasekhaya buqhubele phambili uphuhliso olungcono kumantla nasezantsi. Iimveliso zentsimbi zasekhaya nazo zisungula iimveliso zentsimbi ezikhethekileyo zesilicon. Umlibo wokuzalwa unohlelo olulungileyo lweemveliso zeemeko ezahlukeneyo zesicelo. Nazi iindlela ezimbalwa ezicacileyo zokudibana nazo:

1. Lungiselela isiphaluka semagnethi

Ukuphucula isekethe yemagnethi, ukuba ichaneke, kukwandisa i-sine yomhlaba wemagnethi. Oku kubalulekile, kungekuphela nje kwiimotor zokungenisa amaza. Iimotor zokwenziwa kwamaxesha ahlukeneyo kunye neemotor ezihambelanayo zibalulekile. Xa ndandisebenza kumashishini oomatshini belaphu, ndenza iimotor ezimbini ezinentsebenzo eyahlukeneyo ukunciphisa iindleko. Ngokuqinisekileyo, eyona nto ibaluleke kakhulu yayibubukho okanye ukungabikho kwezibonda ezigobileyo, ezibangele iimpawu ze-sinusoidal ezingahambelaniyo ze-air gap magnetic field. Ngenxa yokusebenza ngesantya esiphezulu, ilahleko yentsimbi yenza umlinganiselo omkhulu, okubangela ukuba kubekho umahluko omkhulu kwiilahleko phakathi kweenjini ezimbini. Ekugqibeleni, emva kokubala okubuyela ngasemva, umahluko welahleko yentsimbi yemoto phantsi kwe-algorithm yolawulo iye yanda ngokuphindwe kabini. Oku kukwakhumbuza wonke umntu ukuba adibanise ii-algorithms zolawulo xa kusenziwa iimotor zolawulo lwesantya esiguqukayo kwakhona.

2.Ukunciphisa ukuxinana kwamagnetic

Ukwandisa ubude bombindi wentsimbi okanye ukwandisa ummandla wokuqhuba kazibuthe wesekethe yamagnetic ukunciphisa ukuxinana kwemagnethi, kodwa isixa sentsimbi esetyenziswa kwimotor siyanda ngokufanelekileyo;

3.Ukunciphisa ubukhulu beetshiphu zentsimbi ukunciphisa ilahleko ye-current induced current

Ukutshintsha amashiti ensimbi e-silicon ashushu aqengqeleke ashushu kunye namaphepha entsimbi e-silicon anokunciphisa ubukhulu bamashiti ensimbi ye-silicon, kodwa iitshiphu zentsimbi ezibhityileyo ziya konyusa inani leetshiphusi zentsimbi kunye neendleko zokwenza iimoto;

4. Ukwamkela iishiti zentsimbi ze-silicon eziqengqelekayo ezibandayo ezine-conductivity entle kazibuthe ukunciphisa ilahleko ye-hysteresis;

5.Ukwamkela i-high-performance iron chip insulation coating;

I-6.Unyango lokushisa kunye neteknoloji yokuvelisa

Uxinzelelo olushiyekileyo emva kokusetyenzwa kweetshiphu zentsimbi kunokuchaphazela kakhulu ukulahleka kwemoto. Xa kusetyenzwa ngamashiti ensimbi ye-silicon, isalathiso sokusika kunye noxinzelelo lwe-punching shear kunempembelelo enkulu ekulahlekeni kombindi wentsimbi. Ukusika ecaleni kwendlela yokuqengqeleka ye-silicon steel sheet kunye nokuqhuba unyango lobushushu kwiphepha lentsimbi le-silicon kunokunciphisa ilahleko nge-10% ukuya kwi-20%.

Ixesha lokuposa: Nov-01-2023