Iimotoumngxuma awukho nto, usebenza kakuhle ekuchitheni ubushushu kwaye unokukhuthaza ukukhanya okukhaphukhaphu kweimoto.Ngaphambili, ii-motor shafts zaziqinile kakhulu, kodwa ngenxa yokusetyenziswa kwee-motor shafts, uxinzelelo lwaluhlala lugxile kumphezulu we-shaft, kwaye uxinzelelo olusembindini lwaluncinci. Ngokweempawu zokugoba kunye nokujika kwe-mechanics yezinto eziphathekayo, inxalenye yangaphakathi ye-imotoUmngxuma wawungcwatywe ngokufanelekileyo, kwaye kwakufuneka ububanzi obuncinci bangaphandle kuphela ukwandisa inxalenye engaphandle. Umngxuma ongcwatywe unokufikelela ekusebenzeni okufanayo kunye nomsebenzi wengxuma eqinileyo, kodwa ubunzima bawo bunokuncipha kakhulu. Okwangoku, ngenxa yokungcwatywa komngxumaimotoi-shaft, ioyile yokupholisa ingangena ngaphakathi kwe-shaft yemoto, yandisa indawo yokusasaza ubushushu kwaye iphucule ukusebenza kakuhle kokusasaza ubushushu. Phantsi kwendlela yangoku yokutshaja ngokukhawuleza kwe-800V high-voltage, inzuzo ye-hollow motor shafts inkulu. Iindlela zangoku zokuvelisa i-hollow motor shafts ziquka ikakhulu i-solid shaft hollowing, i-welding, kunye ne-integrated forming, apho i-welding kunye ne-integrated forming zisetyenziswa kakhulu kwimveliso.

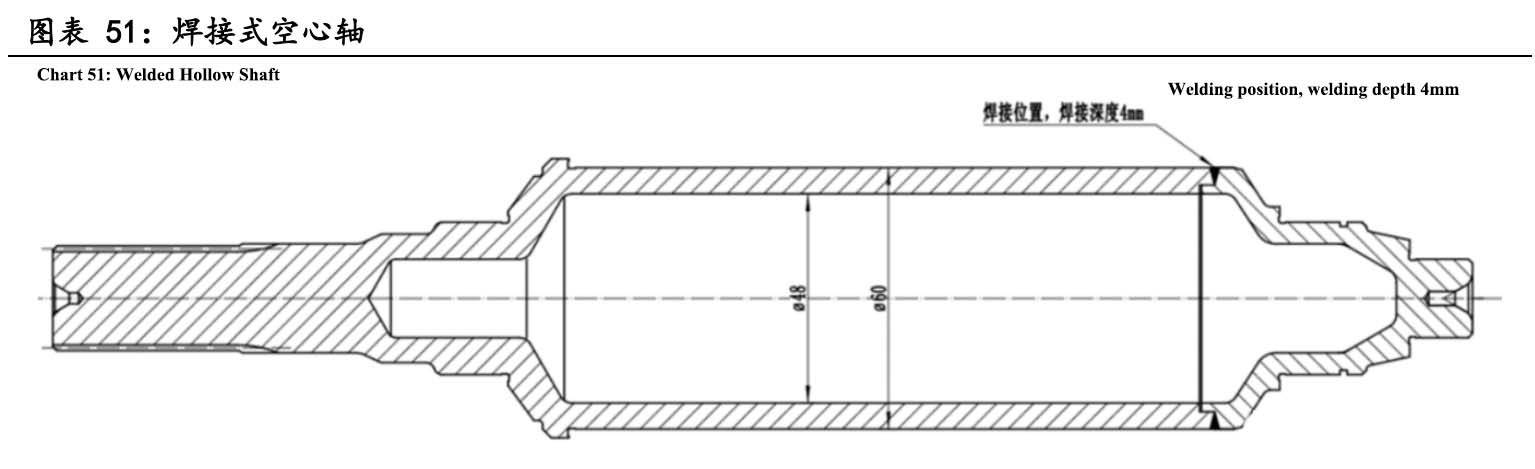

Umngxuma ongenanto odibeneyo ufezekiswa ngokuyila i-extrusion ukuze kufunyanwe umngxuma ongaphakathi onamathelisiweyo, uze emva koko ucutshungulwe ngomatshini uze udityaniswe ube yimo. Ngokubumba i-extrusion, utshintsho kwimo yomngxuma ongaphakathi kunye nesakhiwo semveliso kunye neemfuno zamandla zigcinwa kangangoko kunokwenzeka. Ngokubanzi, ubukhulu bodonga olusisiseko lwemveliso lunokwakhiwa ngaphantsi kwe-5mm. Izixhobo zokuluka ngokubanzi zisebenzisa i-butt friction welding okanye i-laser welding. Ukuba kusetyenziswa i-butt friction welding, indawo ye-butt joint ngokubanzi imalunga ne-3mm welding protrusion. Ukusebenzisa i-laser welding, ubunzulu be-welding ngokubanzi buphakathi kwe-3.5 kunye ne-4.5mm, kwaye amandla e-welding anokuqinisekiswa ukuba aphezulu kune-80% ye-substrate. Abanye ababoneleli banokufikelela ngaphezu kwe-90% yamandla e-substrate ngokusebenzisa amanyathelo olawulo olungqongqo lwenkqubo. Emva kokuba i-welding ye-hollow shaft igqityiwe, kuyimfuneko ukwenza uvavanyo lwe-ultrasonic okanye lwe-X-ray kwisakhiwo se-micro kunye nomgangatho we-weld wendawo yokuluka ukuqinisekisa ukuhambelana kwemveliso.

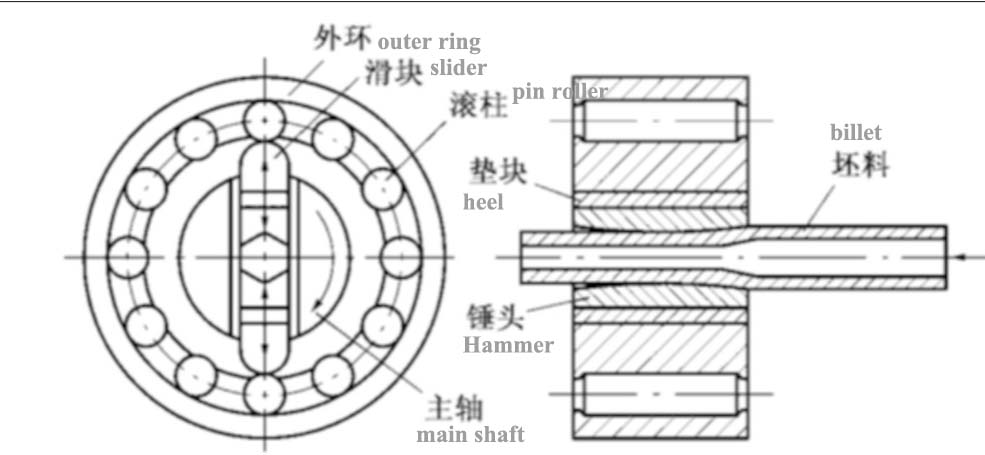

I-shaft edibeneyo yokwenza umngxuma iqulunqwe kakhulu zizixhobo zangaphandle kwindawo engenanto, nto leyo evumela ukuba inxalenye yangaphakathi ifikelele ngqo kumngxuma ongaphakathi onamathelisiweyo we-shaft. Okwangoku, i-radial forging kunye ne-rotary forging zisetyenziswa kakhulu, kwaye izixhobo zingeniswa kakhulu. I-radial forging iqhelekile kwizixhobo zenkampani ye-FELLS, ngelixa i-rotary forging iqhelekile kwizixhobo zenkampani ye-GFM. I-radial forging ngokuqhelekileyo ifezekiswa ngokusebenzisa ii-hammer ezine okanye ngaphezulu ezilinganayo kwi-frequency engaphezulu kwama-240 ngomzuzu ukuze kufezekiswe ukuguqulwa okuncinci kwe-blank kunye ne-direct hollow tube blank forming. I-rotary forging forming yinkqubo yokulungelelanisa iintloko ezininzi ze-hammer ngokulinganayo kwicala elijikelezileyo le-billet. Intloko ye-hammer ijikeleza i-axis ngelixa isenza i-radial high-frequency forging kwindawo yokusebenza, inciphisa ubungakanani be-cross-sectional ye-billet kwaye yolulwe nge-axial ukuze kufumaneke i-workpiece. Xa kuthelekiswa nee-shafts zemveli eziqinileyo, iindleko zokuvelisa ii-shafts ezingenanto ezenziweyo ziya kwanda malunga nama-20%, kodwa ubunzima bee-motor shafts ngokuqhelekileyo buya kuncitshiswa ngama-30-35%.

Ixesha lokuthumela: Septemba-15-2023