1. Intshayelelo kwiiMoto zoMbane

Injini yombane sisixhobo esiguqula amandla ombane abe ngamandla oomatshini. Sisebenzisa ikhoyili enikwe amandla (oko kukuthi, i-stator winding) ukuvelisa intsimi yemagnethi ejikelezayo kwaye isebenze kwi-rotor (njengesakhelo se-aluminium esivaliweyo sekheyiji ye-squirrel) ukwenza i-torque ejikelezayo ye-magnetoelectric.

Iimoto zombane zahlulwe zaba ziimoto zeDC kunye neemoto zeAC ngokwemithombo yamandla eyahlukeneyo esetyenzisiweyo. Uninzi lweemoto kwinkqubo yamandla ziimoto zeAC, ezinokuba ziimoto ezihambelanayo okanye iimoto ezingafaniyo (isantya se-stator magnetic field semoto asigcini isantya esihambelanayo nesantya sokujikeleza kwe-rotor).

Injini yombane ikakhulu ine-stator kunye ne-rotor, kwaye ulwalathiso lwamandla asebenza kwintambo enikwe amandla kwi-magnetic field lunxulumene nolwalathiso lwamandla akhoyo kunye nolwalathiso lomgca wokungenisa amandla akhoyo (ulwalathiso lwe-magnetic field). Umgaqo wokusebenza wenjini yombane sisiphumo sentsimi ye-magnetic kumandla asebenza kwi-current, nto leyo ebangela ukuba imoto ijikeleze.

2. Icandelo leemoto zombane

① Uhlu ngokwesibonelelo samandla esisebenzayo

Ngokwemithombo yamandla ahlukeneyo asebenzayo eemoto zombane, zinokwahlulwa zibe ziimoto zeDC kunye neemoto zeAC. Iimoto zeAC zahlulwe zibe ziimoto zesigaba esinye kunye neemoto zesigaba sesithathu.

② Ukwahlulahlula ngokwesakhiwo kunye nomgaqo wokusebenza

Iimoto zombane zinokwahlulwa zibe ziimoto zeDC, iimoto ezingasebenziyo, kunye neemoto ezihambelanayo ngokwesakhiwo sazo kunye nomgaqo wazo wokusebenza. Iimoto ezihambelanayo zinokwahlulwa zibe ziimoto ezihlala zihleli ezihambelanayo zemagnethi, iimoto ezingasebenziyo ezingafuniyo, kunye neemoto ezihambelanayo zehysteresis. Iimoto ezingasebenziyo zinokwahlulwa zibe ziimoto ezisetyenziswayo kunye neemoto ze-AC commutator. Iimoto ezisetyenziswayo zahlulwa zibe ziimoto ezingasebenziyo zesigaba sesithathu kunye neemoto ezisebenzisa i-pole enemibala eqaqambileyo. Iimoto ezisetyenziswayo ze-AC commutator zahlulwe zibe ziimoto eziqhutywayo zesigaba esinye, iimoto ze-AC DC ezimbini, kunye neemoto ezirhabaxa.

③ Ihlelwe ngokwendlela yokuqalisa kunye nendlela yokusebenza

Iimoto zombane zingahlulwa zibe ziimoto eziqala nge-capacitor enye yesigaba esinye ezingasebenziyo, iimoto eziqala nge-capacitor enye yesigaba esinye ezisebenza nge-capacitor, iimoto eziqala nge-capacitor enye yesigaba esinye ezingasebenziyo, kunye neemoto eziqala nge-asynchronous zesigaba esinye ngokweendlela zazo zokuqala nezokusebenza.

④ Ukwahlulahlula ngokwenjongo

Iimoto zombane zingahlulwa zibe ziimoto eziqhubayo kunye neemoto zokulawula ngokwenjongo yazo.

Iimoto zombane zokuqhuba zahlulwe zibe zizixhobo zombane (kubandakanya ukubhola, ukupolisha, ukupolisha, ukukrola, ukusika, kunye nokwandisa izixhobo), iimoto zombane zezixhobo zasekhaya (kubandakanya oomatshini bokuhlamba, iifeni zombane, iifriji, ii-air conditioner, iirekhoda, iirekhoda zevidiyo, abadlali beDVD, abacoci be-vacuum, iikhamera, ii-electrical blowers, ii-electrical shavers, njl.njl.), kunye nezinye izixhobo ezincinci zoomatshini (kubandakanya izixhobo ezahlukeneyo zoomatshini abancinci, oomatshini abancinci, izixhobo zonyango, izixhobo ze-elektroniki, njl.njl.).

Iimoto zokulawula zahlulwe ngakumbi zaba ziimoto ze-stepper kunye neemoto ze-servo.

⑤ Uhlu ngokwesakhiwo serotor

Ngokwesakhiwo serotor, iimoto zombane zingahlulwa zibe ziimoto zokungenisa iikheyiji (ezaziwa ngaphambili ngokuba ziimoto ze-squirrel cage asynchronous) kunye neemoto zokungenisa ii-wound rotor (ezaziwa ngaphambili ngokuba ziimoto ze-wound asynchronous).

⑥ Ihlelwe ngokwesantya sokusebenza

Iimoto zombane zinokwahlulwa zibe ziimoto ezinesantya esiphezulu, iimoto ezinesantya esiphantsi, iimoto ezinesantya esingaguqukiyo, kunye neemoto ezinesantya esiguquguqukayo ngokwesantya sazo sokusebenza.

⑦ Uhlu ngokwendlela yokukhusela

a. Uhlobo oluvulekileyo (olufana ne-IP11, i-IP22).

Ngaphandle kwesakhiwo senkxaso esifunekayo, injini ayinalo ukhuseleko olukhethekileyo kwiindawo ezijikelezayo neziphilayo.

b. Uhlobo oluvaliweyo (olufana ne-IP44, i-IP54).

Iindawo ezijikelezayo neziphilayo ngaphakathi kwebhokisi yemoto zifuna ukhuseleko oluyimfuneko loomatshini ukuthintela ukudibana ngengozi, kodwa oko akuthinteli kakhulu umoya. Iimoto ezikhuselayo zahlulwe zibe zezi ntlobo zilandelayo ngokweendlela ezahlukeneyo zomoya kunye nolwakhiwo lwazo lokhuseleko.

ⓐ Uhlobo lwesigqubuthelo se-mesh.

Imingxuma yomoya yemoto igqunywe zizigqubuthelo ezineembobo ukuthintela iindawo ezijikelezayo neziphilayo zemoto ukuba zingadibani nezinto zangaphandle.

ⓑ Ayinamanzi.

Ulwakhiwo lomoya wokungenisa umoya lunokuthintela ulwelo okanye izinto eziqinileyo eziwela ngokuthe nkqo ukuba zingangeni ngqo ngaphakathi kwemoto.

ⓒ Ayinakusetyenziswa xa kutshizwa.

Ulwakhiwo lwe-motor vent lunokuthintela ulwelo okanye izinto eziqinileyo ukuba zingangeni ngaphakathi kwe-motor nangayiphi na indlela ngaphakathi koluhlu lwe-engile ethe nkqo ye-100 °.

ⓓ Ivaliwe.

Ulwakhiwo lwebhokisi yemoto lunokuthintela ukutshintshiselana komoya ngaphakathi nangaphandle kwebhokisi, kodwa aludingi ukutywinwa ngokupheleleyo.

ⓔ Ayinamanzi.

Ulwakhiwo lwebhokisi yemoto lunokuthintela amanzi anoxinzelelo oluthile ukuba angangeni ngaphakathi kwemoto.

ⓕ Ayinamanzi.

Xa injini intywiliselwa emanzini, ulwakhiwo lwebhokisi yenjini lunokuthintela amanzi ukuba angangeni ngaphakathi kwenjini.

ⓖ Indlela yokuntywila.

Injini yombane ingasebenza emanzini ixesha elide phantsi koxinzelelo lwamanzi olulinganisiweyo.

ⓗ Ubungqina bokuqhuma.

Ulwakhiwo lwebhokisi yemoto lwanele ukuthintela ukuqhuma kwegesi ngaphakathi kwemoto ukuba kungadluliselwa ngaphandle kwemoto, nto leyo ebangela ukuqhuma kwegesi evuthayo ngaphandle kwemoto. Ingxelo esemthethweni ethi “Mechanical Engineering Literature”, isikhululo sepetroli sobunjineli!

⑧ Ihlulwe ngokweendlela zokungenisa umoya kunye neendlela zokupholisa

a. Ukuzipholisa.

Iimoto zombane zixhomekeke kuphela kwimitha engaphezulu kunye nokuhamba komoya wendalo ukuze ziphole.

b. Ifeni ezipholisele ngokwayo.

Injini yombane iqhutywa yifeni enika umoya opholileyo ukuze upholise umphezulu okanye ingaphakathi lenjini.

c. Ifeni yakhe yaphola.

Ifeni enika umoya opholileyo ayiqhutywa yimoto yombane ngokwayo, kodwa iqhutywa ngokuzimeleyo.

d. Uhlobo lokungenisa umoya kwimibhobho.

Umoya opholileyo awungeniswa ngqo okanye awukhutshelwa ngaphandle kwemoto okanye ngaphakathi kwemoto, kodwa ungeniswa okanye ukhutshelwa ngaphandle kwemoto ngemibhobho. Iifeni zokungenisa umoya kwimibhobho zinokupholiswa yifeni okanye zipholiswe ngenye ifeni.

e. Ukupholisa ulwelo.

Iimoto zombane zipholiswa lulwelo.

f. Ukupholisa igesi yesekethe evaliweyo.

Ukujikeleza okuphakathi kokupholisa imoto kukwisekethe evaliweyo equka imoto kunye ne-cooler. I-cooling medium ifunxa ubushushu xa idlula kwimoto kwaye ikhuphe ubushushu xa idlula kwi-cooler.

g. Ukupholisa umphezulu kunye nokupholisa kwangaphakathi.

Isixhobo sokupholisa esingadluliyo ngaphakathi komqhubi wemoto sibizwa ngokuba yi-surface cooling, ngelixa isixhobo sokupholisa esidlula ngaphakathi komqhubi wemoto sibizwa ngokuba yi-internal cooling.

⑨ Uhlu ngokwemo yesakhiwo sofakelo

Uhlobo lokufakelwa kweemoto zombane ludla ngokumelwa ziikhowudi.

Le khowudi imelwe sisifinyezo se-IM sofakelo lwamazwe ngamazwe,

Unobumba wokuqala kwi-IM umele ikhowudi yohlobo lofakelo, u-B umele ukufakwa okuthe tye, kwaye u-V umele ukufakwa okuthe tye;

Inombolo yesibini imele ikhowudi yophawu, emelwe ngamanani esiArabhu.

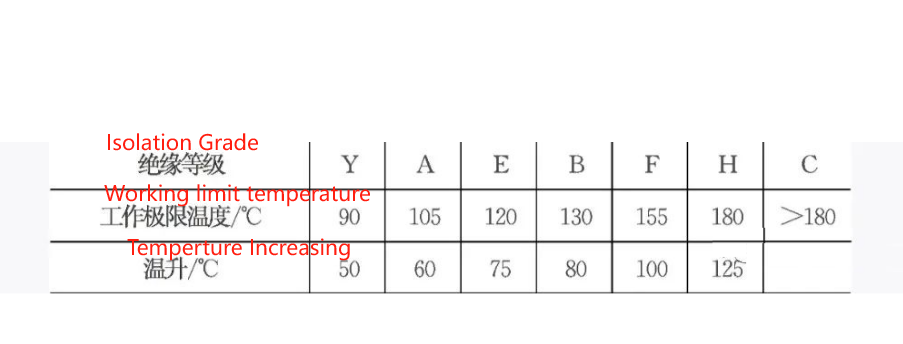

⑩ Uhlu ngokwenqanaba lobushushu

Inqanaba le-A, inqanaba le-E, inqanaba le-B, inqanaba le-F, inqanaba le-H, inqanaba le-C. Uhlu lwenqanaba lokufakwa kweemoto luboniswe kwitheyibhile engasezantsi.

⑪ Ihlelwe ngokweeyure zokusebenza ezilinganisiweyo

Inkqubo yokusebenza eqhubekayo, eqhubekayo, neyexesha elifutshane.

Inkqubo Yomsebenzi Oqhubekayo (SI). Le moto iqinisekisa ukusebenza kwexesha elide phantsi kwexabiso elilinganisiweyo elichazwe kwi-nameplate.

Iiyure zokusebenza zexesha elifutshane (S2). Injini inokusebenza ixesha elithile kuphela phantsi kwexabiso elilinganisiweyo elichazwe kwi-nameplate. Kukho iintlobo ezine zemigangatho yexesha lokusebenza kwexesha elifutshane: imizuzu eli-10, imizuzu engama-30, imizuzu engama-60, kunye nemizuzu engama-90.

Inkqubo yokusebenza engapheliyo (S3). Injini ingasetyenziswa kuphela ngamaxesha athile nangaphantsi kwexabiso elilinganisiweyo elichazwe kwi-nameplate, elichazwe njengepesenti yemizuzu eli-10 ngomjikelo ngamnye. Umzekelo, i-FC=25%; Phakathi kwazo, i-S4 ukuya kwi-S10 ziyinxalenye yeenkqubo ezininzi zokusebenza ezingasebenzi rhoqo phantsi kweemeko ezahlukeneyo.

9.2.3 Iimpazamo eziqhelekileyo zeemoto zombane

Iimoto zombane zihlala zidibana neempazamo ezahlukeneyo ngexesha lokusebenza ixesha elide.

Ukuba ukuhanjiswa kwe-torque phakathi kwesixhumi kunye ne-reducer kukhulu, umngxuma wokudibanisa kumphezulu we-flange ubonisa ukuwohloka okukhulu, okwandisa umsantsa wokulingana konxibelelwano kwaye kukhokelela kukudluliselwa kwe-torque okungazinzanga; Ukuwohloka kwendawo yokuthwala okubangelwa kukonakala kwe-bearing ye-motor shaft; Ukuwohloka phakathi kweentloko ze-shaft kunye neendlela eziphambili, njl. Emva kokuba kubekho iingxaki ezinjalo, iindlela zemveli zigxila kakhulu ekulungiseni ukuwelda okanye ekuchwethezeni emva kokufakelwa kwebrashi, kodwa zombini zineengxaki ezithile.

Uxinzelelo lobushushu olubangelwa kukuwelda kokulungisa ubushushu obuphezulu alunakususwa ngokupheleleyo, olunokugoba okanye ukwaphuka; Nangona kunjalo, i-brush plating inqunyelwe bubukhulu bengubo kwaye iyakwazi ukuxobuka, kwaye zombini ezi ndlela zisebenzisa isinyithi ukulungisa isinyithi, esingenakutshintsha ubudlelwane "bobunzima ukuya kobunzima". Phantsi kwesenzo esidibeneyo samandla ahlukeneyo, siya kuqhubeka sibangela ukuguguleka kwakhona.

Amazwe aseNtshona anamhlanje adla ngokusebenzisa izixhobo zepolymer ezidityanisiweyo njengeendlela zokulungisa ezi ngxaki. Ukusetyenziswa kwezinto zepolymer ukulungisa akuchaphazeli uxinzelelo lobushushu be-welding, kwaye ubukhulu bokulungisa abunamda. Kwangaxeshanye, izinto zesinyithi kwimveliso azinalo ukuguquguquka kokufunxa impembelelo kunye nokungcangcazela kwezixhobo, ziphephe ukuguguleka kwakhona, kwaye zandise ubomi benkonzo yezinto zezixhobo, zisindisa ixesha elininzi lokungasebenzi kwamashishini kwaye zidale ixabiso elikhulu kwezoqoqosho.

(1) Ingxaki: Injini ayinakuqala emva kokuba iqhagamshelwe

Izizathu kunye neendlela zokusingatha zezi zilandelayo.

① Impazamo yocingo olujikeleza i-stator – jonga unxibelelwano locingo uze ulungise impazamo.

② Vula isekethe kwi-stator winding, short circuit grounding, vula isekethe kwi-wound rotor motor – chonga indawo yempazamo uze uyisuse.

③ Umthwalo ogqithisileyo okanye indlela yokudlulisela ebambekileyo – jonga indlela yokudlulisela kunye nomthwalo.

④ Vula isekethe kwisekethe yerotor yemoto yerotor yenxeba (unxibelelwano olubi phakathi kwebhrashi kunye neringi yokutyibilika, isekethe evulekileyo kwi-rheostat, unxibelelwano olubi kwileya, njl.njl.) – chonga indawo yesekethe evulekileyo uze uyilungise.

⑤ I-voltage yombane iphantsi kakhulu - jonga unobangela uze uwususe.

⑥ Ukulahleka kwesigaba sombane – jonga isekethe uze ubuyisele izigaba ezintathu.

(2) Ingxaki: Ubushushu bemoto bunyuka kakhulu okanye butshaya

Izizathu kunye neendlela zokusingatha zezi zilandelayo.

① Igcwele kakhulu okanye iqalwe rhoqo – nciphisa umthwalo kwaye unciphise inani leeqalo.

② Ukulahleka kwesigaba ngexesha lokusebenza – jonga isekethe uze ubuyisele izigaba ezintathu.

③ Impazamo yentambo yokubhida ye-stator - jonga intambo uze uyilungise.

④ I-stator winding iphantsi komhlaba, kwaye kukho i-short circuit phakathi kokujika okanye i-phases - chonga indawo ye-grounding okanye i-short circuit uze uyilungise.

⑤ I-cage rotor winding yaphukile – tshintsha i-rotor.

⑥ Ukungasebenzi kakuhle kwesigaba sokujika kwe-wound rotor – chonga indawo apho kukho impazamo khona uze uyilungise.

⑦ Ukungqubana phakathi kwe-stator kunye ne-rotor – Jonga iibheringi kunye ne-rotor ukuba aziguquguquki, ziyalungiswa okanye ziyatshintshwa.

⑧ Umoya ongenamoya uphantsi – jonga ukuba umoya awuphazanyiswa na.

⑨ I-voltage iphezulu kakhulu okanye iphantsi kakhulu – Jonga unobangela uze uwususe.

(3) Ingxaki: Ukungcangcazela kwemoto okugqithisileyo

Izizathu kunye neendlela zokusingatha zezi zilandelayo.

① I-rotor engalinganiyo – ibhalansi yokulinganisa.

② I-pulley engalinganiyo okanye ulwandiso lomngxuma olugobileyo - jonga uze ululungise.

③ Injini ayihambelani ne-axis yomthwalo - jonga kwaye ulungise i-axis yeyunithi.

④ Ukufakelwa kwemoto ngendlela engafanelekanga – jonga ukufakwa kwayo kunye nezikrufu zesiseko.

⑤ Ukuxinana ngequbuliso – nciphisa umthwalo.

(4) Ingxaki: Isandi esingaqhelekanga ngexesha lokusebenza

Izizathu kunye neendlela zokusingatha zezi zilandelayo.

① Ukungqubana phakathi kwe-stator kunye ne-rotor – Jonga iibheringi kunye ne-rotor ukuba aziguquguquki, ziyalungiswa okanye ziyatshintshwa.

② Iibheringi ezonakeleyo okanye ezingathambisanga kakuhle – tshintsha kwaye ucoce iibheringi.

③ Ukusebenza kokulahleka kwesigaba senjini – jonga indawo yesekethe evulekileyo uze uyilungise.

④ Ukungqubana kweblade nebhokisi - jonga kwaye ususe iimpazamo.

(5) Ingxaki: Isantya semoto siphantsi kakhulu xa siphantsi komthwalo

Izizathu kunye neendlela zokusingatha zezi zilandelayo.

① I-voltage yombane iphantsi kakhulu – jonga i-voltage yombane.

② Umthwalo ogqithisileyo – jonga umthwalo.

③ I-cage rotor winding yaphukile – tshintsha i-rotor.

④ Unxibelelwano olubi okanye oluqhawukileyo lwesigaba esinye seqela lentambo ye-rotor ejikelezayo - jonga uxinzelelo lwebhrashi, unxibelelwano phakathi kwebhrashi kunye neringi yokutyibilika, kunye nonxibelelwano lwe-rotor.

(6) Ingxaki yento: Ibhokisi yemoto iyasebenza

Izizathu kunye neendlela zokusingatha zezi zilandelayo.

① Umhlaba ophantsi okanye ukumelana nomhlaba ophezulu – Qhagamshela ucingo lomhlaba ngokwemigaqo ukuze kususwe iimpazamo ezingalunganga zomhlaba.

② Iifestile zimanzi – ziyanyangwa ukuze zomiswe.

③ Umonakalo wokufakwa kwe-insulation, ukungqubana kwe-lead - Ipeyinti yokuntywila ukuze kulungiswe i-insulation, qhagamshela kwakhona i-leads. 9.2.4 Iinkqubo zokusebenza kwe-motor

① Ngaphambi kokuba uyiqhaqhe, sebenzisa umoya ocinezelweyo ukuvuthuza uthuli olukumphezulu wemoto uze uyisule icocekile.

② Khetha indawo yokusebenzela yokuqhaqha injini uze ucoce indawo ekwindawo yokusebenza.

③ Ndiyazazi iimpawu zesakhiwo kunye neemfuno zobugcisa zokugcinwa kweemoto zombane.

④ Lungisa izixhobo ezifunekayo (kuquka nezixhobo ezikhethekileyo) kunye nezixhobo zokuziqhaqha.

⑤ Ukuze kuqondwe ngakumbi iziphene ekusebenzeni kwemoto, uvavanyo lokuhlola lunokwenziwa ngaphambi kokuba idityaniswe ukuba iimeko ziyavuma. Ngenxa yesi sizathu, imoto ivavanywa ngomthwalo, kwaye ubushushu, isandi, ukungcangcazela, kunye nezinye iimeko zenxalenye nganye yemoto zijongwa ngokweenkcukacha. I-voltage, i-current, isantya, njl.njl. nazo ziyavavanywa. Emva koko, umthwalo uyasuswa kwaye uvavanyo olwahlukileyo lokuhlolwa kwe-no-load lwenziwa ukulinganisa i-no-load current kunye ne-no-load loss, kwaye kwenziwa iirekhodi. Iakhawunti esemthethweni ethi “Mechanical Engineering Literature”, isikhululo sepetroli sobunjineli!

⑥ Sika umbane, susa iingcingo zangaphandle zemoto, uze ugcine iirekhodi.

⑦ Khetha i-voltage megohmmeter efanelekileyo ukuvavanya ukumelana nobushushu bemoto. Ukuze kuthelekiswe amaxabiso okumelana nobushushu obulinganisiweyo ngexesha lokugcinwa kokugqibela ukuze kuchongwe indlela etshintsha ngayo ubushushu kunye nemeko yobushushu bemoto, amaxabiso okumelana nobushushu obulinganisiweyo kumaqondo obushushu ahlukeneyo kufuneka aguqulwe abe kubushushu obufanayo, adla ngokuguqulelwa kwi-75 ℃.

⑧ Vavanya umlinganiselo wokufunxa K. Xa umlinganiselo wokufunxa K>1.33, ibonisa ukuba ubushushu bemoto abuchaphazelekanga kukufuma okanye inqanaba lokufuma alikho qatha. Ukuze kuthelekiswe nedatha yangaphambili, kuyimfuneko ukuguqula umlinganiselo wokufunxa olinganiswe nakweyiphi na iqondo lobushushu ube kubushushu obufanayo.

9.2.5 Ukugcinwa nokulungiswa kweemoto zombane

Xa injini isebenza okanye ingasebenzi kakuhle, kukho iindlela ezine zokuthintela nokususa iimpazamo ngexesha elifanelekileyo, ezizezi, ukujonga, ukumamela, ukuvumba, kunye nokuchukumisa, ukuqinisekisa ukusebenza ngokukhuselekileyo kwenjini.

(1) Jonga

Qaphela ukuba kukho naziphi na iingxaki ngexesha lokusebenza kwemoto, ezibonakala kakhulu kwezi meko zilandelayo.

① Xa i-stator winding ingasebenzi kakuhle, umsi unokubonakala kwi-motor.

② Xa injini igcwele kakhulu okanye ingasebenzi kakuhle, isantya siya kuncipha kwaye kuya kubakho isandi esinzima "esikhwazayo".

③ Xa injini isebenza ngendlela eqhelekileyo, kodwa ngequbuliso ima, iintlantsi zinokubonakala xa uqhagamshelo lukhululekile; Imeko yokuvuthelwa kwefuse okanye inxalenye ibambekile.

④ Ukuba imoto ingcangcazela ngamandla, kusenokuba kungenxa yokuxinana kwesixhobo sothumelo, ukungabambeki kakuhle kwemoto, iibholiti zesiseko ezikhululekileyo, njl.

⑤ Ukuba kukho ukutshintsha kombala, amabala okutsha, kunye namabala omsi kwiindawo ezidityanisiweyo zangaphakathi kunye neendawo ezidityanisiweyo zemoto, oko kubonisa ukuba kunokubakho ubushushu obuphezulu kwindawo ethile, unxibelelwano olubi kwiindawo ezidityanisiweyo ze-conductor, okanye ii-windings ezitshisiweyo.

(2) Mamela

Injini kufuneka ikhuphe isandi esifanayo nesikhaphukhaphu "esikhwazayo" ngexesha lokusebenza okuqhelekileyo, ngaphandle kwengxolo okanye izandi ezikhethekileyo. Ukuba ingxolo eninzi kakhulu ikhutshwa, kuquka ingxolo ye-electromagnetic, ingxolo ye-bearing, ingxolo yomoya, ingxolo yokungqubana koomatshini, njl.njl., isenokuba ngunobangela wokungasebenzi kakuhle.

① Xa kukho ingxolo ye-electromagnetic, ukuba injini ikhupha isandi esikhulu nesinzima, kunokubakho izizathu ezahlukeneyo.

a. Umsantsa womoya phakathi kwe-stator kunye ne-rotor awulingani, kwaye isandi siyatshintshatshintsha ukusuka phezulu ukuya ezantsi ngexesha elifanayo phakathi kwezandi eziphezulu nezisezantsi. Oku kubangelwa kukuwohloka kweebheringi, okubangela ukuba i-stator kunye ne-rotor zingabi ngqindilili.

b. Umsinga we-three-phase awulingani. Oku kungenxa yokungafakwa kakuhle komhlaba, i-short circuit, okanye unxibelelwano olubi lwe-three-phase winding. Ukuba isandi sincinci kakhulu, oko kubonisa ukuba injini igcwele kakhulu okanye iphelelwa yi-phase.

c. Umongo wentsimbi okhululekileyo. Ukungcangcazela kwemoto ngexesha lokusebenza kubangela ukuba iibholithi zokulungisa umongo wentsimbi zikhululeke, nto leyo ebangela ukuba ishidi lesinyithi lesilicon lomongo wentsimbi likhululeke kwaye likhuphe ingxolo.

② Kwingxolo yebheri, kufuneka ijongwe rhoqo ngexesha lokusebenza kwemoto. Indlela yokubeka iliso kukucinezela elinye icala le-screwdriver kwindawo yokufakela yebheri, kwaye elinye icala likufutshane nendlebe ukuze uve isandi sebheri sisebenza. Ukuba ibheri isebenza ngokwesiqhelo, isandi sayo siya kuba sisandi esiqhubekayo nesincinci "esirhawuzelayo", ngaphandle kokutshintshatshintsha kokuphakama okanye isandi sokungqubana kwesinyithi. Ukuba ezi zandi zilandelayo zenzeka, zithathwa njengezingaqhelekanga.

a. Kukho isandi "esitshoyo" xa i-bearing isebenza, esisandi sokungqubana kwesinyithi, esidla ngokubangelwa kukungabikho kweoyile kwi-bearing. I-bearing kufuneka ihlulwe kwaye yongezwe nge-grease efanelekileyo yokuthambisa.

b. Ukuba kukho isandi "esikrwempayo", sisandi esenziwa xa ibhola ijikeleza, esidla ngokubangelwa kukoma kwegrisi yokuthambisa okanye ukungabikho kweoyile. Kungongezwa isixa esifanelekileyo segrisi.

c. Ukuba kukho isandi "sokuklikha" okanye "sokuklikha", sisandi esiveliswa kukuhamba okungacwangciswanga kwebhola kwi-bearing, okubangelwa kukonakala kwebhola kwi-bearing okanye ukusetyenziswa kwexesha elide kwemoto, kunye nokomisa kwegrisi yokuthambisa.

③ Ukuba indlela yokudlulisa kunye nendlela eqhutywa ngayo ikhupha izandi eziqhubekayo endaweni yokuguquguquka, zinokuphathwa ngale ndlela ilandelayo.

a. Izandi ezithi “popping” eziphindaphindwayo zibangelwa ziibhanti ezingalinganiyo.

b. Isandi esithi “thumping” esiphindaphindwayo sibangelwa kukudibana okukhululekileyo okanye i-pulley phakathi kwee-shafts, kunye nezitshixo ezigugileyo okanye iindlela zesitshixo.

c. Isandi sokungqubana okungalinganiyo sibangelwa ziincakuba zomoya ezingqubana nesigqubuthelo sefeni.

(3) Ivumba

Ngokuva ivumba lemoto, iimpazamo zinokuchongwa kwaye zithintelwe. Ukuba kufunyenwe ivumba elikhethekileyo lepeyinti, libonisa ukuba ubushushu bangaphakathi bemoto buphezulu kakhulu; Ukuba kufunyenwe ivumba elinamandla lokutsha okanye lokutsha, lisenokuba libangelwa kukwaphuka komaleko wokugquma okanye ukutsha kwe-winding.

(4) Ukuchukumisa

Ukuchukumisa ubushushu bezinye iindawo zemoto kunokumisela unobangela wokungasebenzi kakuhle. Ukuqinisekisa ukhuseleko, umva wesandla kufuneka usetyenziselwe ukuchukumisa iindawo ezijikelezileyo zebhokisi yemoto kunye neebheringi xa uchukumisa. Ukuba kufunyenwe ukungaqheleki kobushushu, kunokubakho izizathu ezahlukeneyo.

① Umoya ophantsi. Okufana nokuvaleka kwefeni, imibhobho yomoya evalekileyo, njl.

② Ukulayisha kakhulu. Kubangela umbane ogqithisileyo kunye nokugqithisa kakhulu kwe-stator winding.

③ Ukujikeleza okufutshane phakathi kwee-stator windings okanye ukungalingani komsinga wesigaba sesithathu.

④ Ukuqalisa okanye ukuqhobosha rhoqo.

⑤ Ukuba ubushushu obujikeleze ibheriya buphezulu kakhulu, bunokubangelwa kukonakala kwebheriya okanye ukungabikho kweoyile.

Ixesha lokuthumela: Okthobha-06-2023